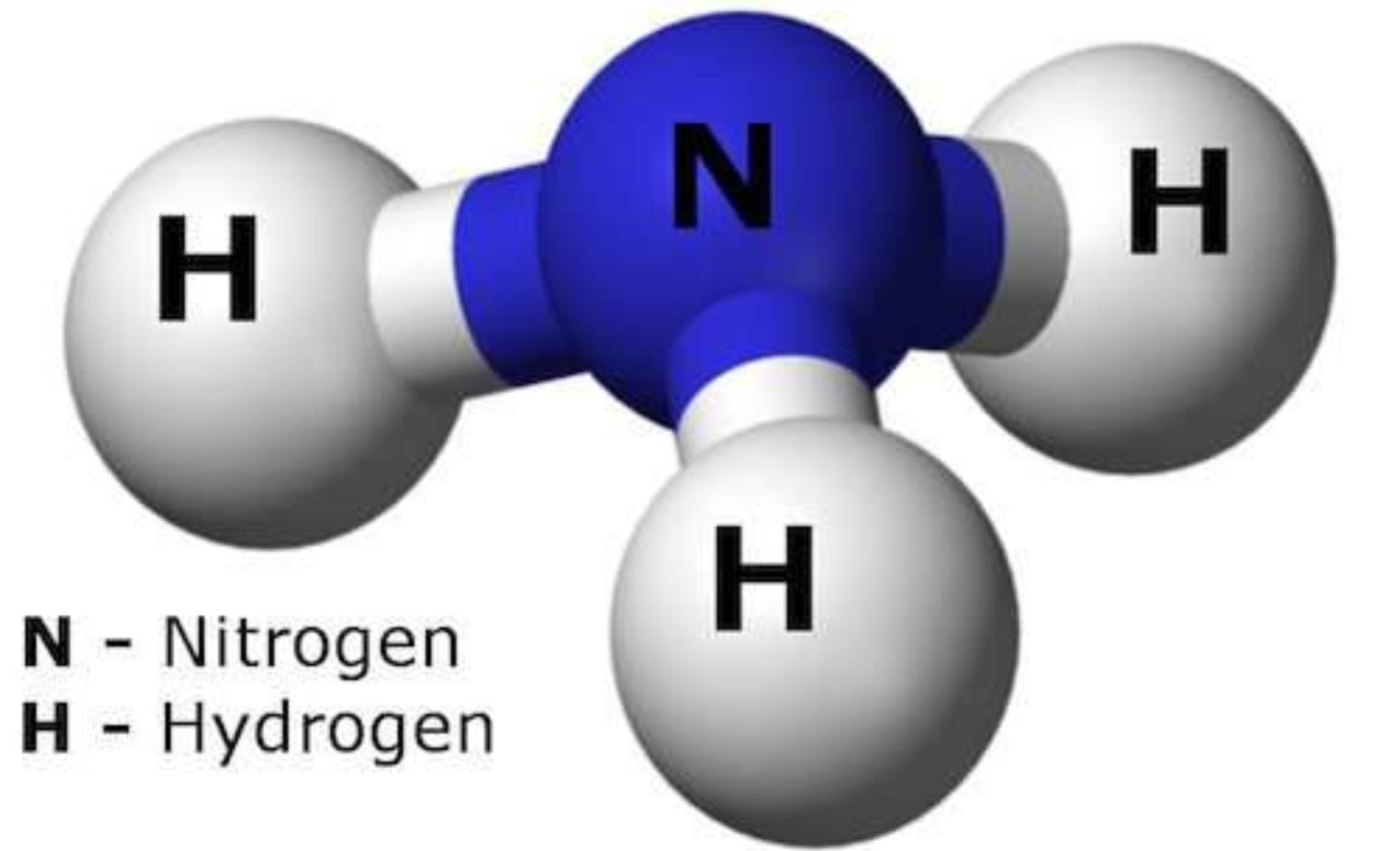

Update on Ammonia Engine Combustion Using Direct Fuel Injection Christopher Gross, George Zacharakis-Jutz Song-Charng Kong Department of Mechanical Engineering Iowa State University Acknowledgements: Iowa Energy Center; Norm Olson Robert Bosch; National Instruments Department of Mechanical Engineering, Iowa State University 2 Thermodynamics/Chemistry • Stoichiometric chemical reaction 3 22 2 2 NH O N H O N + ⋅ + ⋅ →⋅ + ⋅ 0.75 ( 3.76 ) 1.5 3.32 Fuel Molecule Boiling Point (°C) (Air/Fuel)s Latent Heat (kJ/kg) Energy Content (MJ/kg-fuel) Energy Content (MJ/kgstoichiometric mixture) Methanol CH3OH 64.7 6.435 1203 20 2.6900 Ethanol C2H5OH 78.4 8.953 850 26.9 2.7027 Gasoline C7H17 — 15.291 310 44 2.5781 Diesel C14.4H24.9 — 14.3217 230 42.38 2.7660 Ammonia NH3 –33.5 6.0456 1371 18.6103 2.6414 Department of Mechanical Engineering, Iowa State University 3 Approaches • CI engine operation • Port induction of gaseous ammonia, ignited by directl Department of Mechanical Engineering, Iowa State University NH3/DME • Use direct liquid fuel injection • Confine combustion mixture near the center • To reduce exhaust ammonia emissions • Dimethyl ether (CH3-O-CH3) as ignition source • Fuel mixing and storage at high pressure • New fuel injection system – without fuel return • Injection pump, injector, electronic control • Various NH3/DME ratios 4 Fuel injector Department of Mechanical Engineering, Iowa State University Engine Setup • Yanmar diesel engine (L70V, 320 c.c.) • Rated power at 6.26 hp at 3,480 rpm • Developed new fuel injection and engine control systems • Bosch GDI type injector (up to 200 bar injection pressure) Department of Mechanical Engineering, Iowa State University Setup • Mixing and storage of ammonia/DME at high pressure • Exhaust emissions measurements • Horiba MEXA-7100DEGR (CO2, CO, O2, HC) • Horiba 1170NX (NOx, NH3) • AVL Smoke Meter (PM) Fuel mixing system Emissions analyzers Department of Mechanical Engineering, Iowa State University 0 1 2 3 4 5 6 7 2200 2400 2600 2800 3000 3200 3400 3600 Power [HP] Engine Speed [RPM] Maximum Power Output utilizing different Fuels Diesel (baseline) 100% DME 20%NH3-80%DME 40%NH3-60%DME • Challenges • Latent heat • Flame speed • Low to medium loads at various speeds Heat of Vaporization Flame Speed Diesel Fuel Operating Range Department of Mechanical Engineering, Iowa State University Mode Engine Speed (rpm) Engine Power (kW) Engine Torque (Nm) 5 2548 1.74 6.61 7 2548 0.87 3.31 9 2895 1.05 3.52 11 3243 1.12 3.34 20 2200 1.47 6.47 21 2200 0.74 3.24 Test Conditions Fuel SOI (btdc) P_inj T_intake air 100%DME 0 ~ 30 150 bar 30 C 20%NH3-80%DME 5 ~ 35 150 bar 60 C 40%NH3-60%DME 15 ~ 40 180 bar 80 C 60%NH3-40%DME 140 ~ 180 205 bar 90 C Results will be presented first Department of Mechanical Engineering, Iowa State University 0 5 10 15 20 25 -10 0 10 20 30 40 50 60 70 -75 -60 -45 -30 -15 0 15 30 45 60 75 HRR (J/deg) Cylinder Pressure (bar) Crank Angle (deg) 100%DME 20%NH3-80%DME 40%NH3-60%DME Mode 5 SOI = 20 BTDC 0 5 10 15 20 25 -10 0 10 20 30 40 50 60 70 -75 -60 -45 -30 -15 0 15 30 45 60 75 HRR (J/deg) Cylinder Pressure (bar) Crank Angle (deg) 100%DME 20%NH3-80%DME 40%NH3-60%DME Mode 7 SOI = 15 BTD Department of Mechanical Engineering, Iowa State University • Observation on combustion • No significant deterioration of combustion • More ammonia longer ignition delays, more significant premixed combustion • Reporting emissions • Reported in BSEC [MJ/kWh] (instead of BSFC [g/kWh]) • Imply the fuel energy consumption rate, fuel economy • As reference: @ 3,250 rpm and 4.3kW running on diesel fuel • BSEC is 13.656 MJ/kWh, corresponding to a BSFC of 304.8 g/kWh for the current engine. Results Department of Mechanical Engineering, Iowa State University 0 5 10 15 20 25 30 20 30 40 50 60 70 80 NOx (g/kWh) BSEC (MJ/kWh) Mode 5 Single Injection, 100% DME Mode 7 Mode 9 Mode 11 Mode 20 Mode 21 0 5 10 15 20 25 30 20 30 40 50 60 70 80 NOx (g/kWh) BSEC (MJ/kWh) Single Injection, 20%NH3 – 80%DME Mode 5 Mode 7 Mode 9 Mode 11 Mode 20 Mode 21 0 5 10 15 20 25 30 0 10 20 30 40 50 60 70 80 NOx (g/kWh) BSEC (MJ/kWh) Mode 3 Single Injection, 40%NH3 – 60%D

ZERO CARBON EMISSIONS