Promising Results for Ammonia Tested in Combustion Engine

The technology group Wärtsilä has commenced combustion trials using ammonia on both dual-fuel and spark-ignited gas engines with promising results.

As part of the tests, ammonia was injected into a combustion research unit to better understand its properties. The tests will be followed by field tests in collaboration with shipowners from 2022 and potentially also with energy customers in the future.

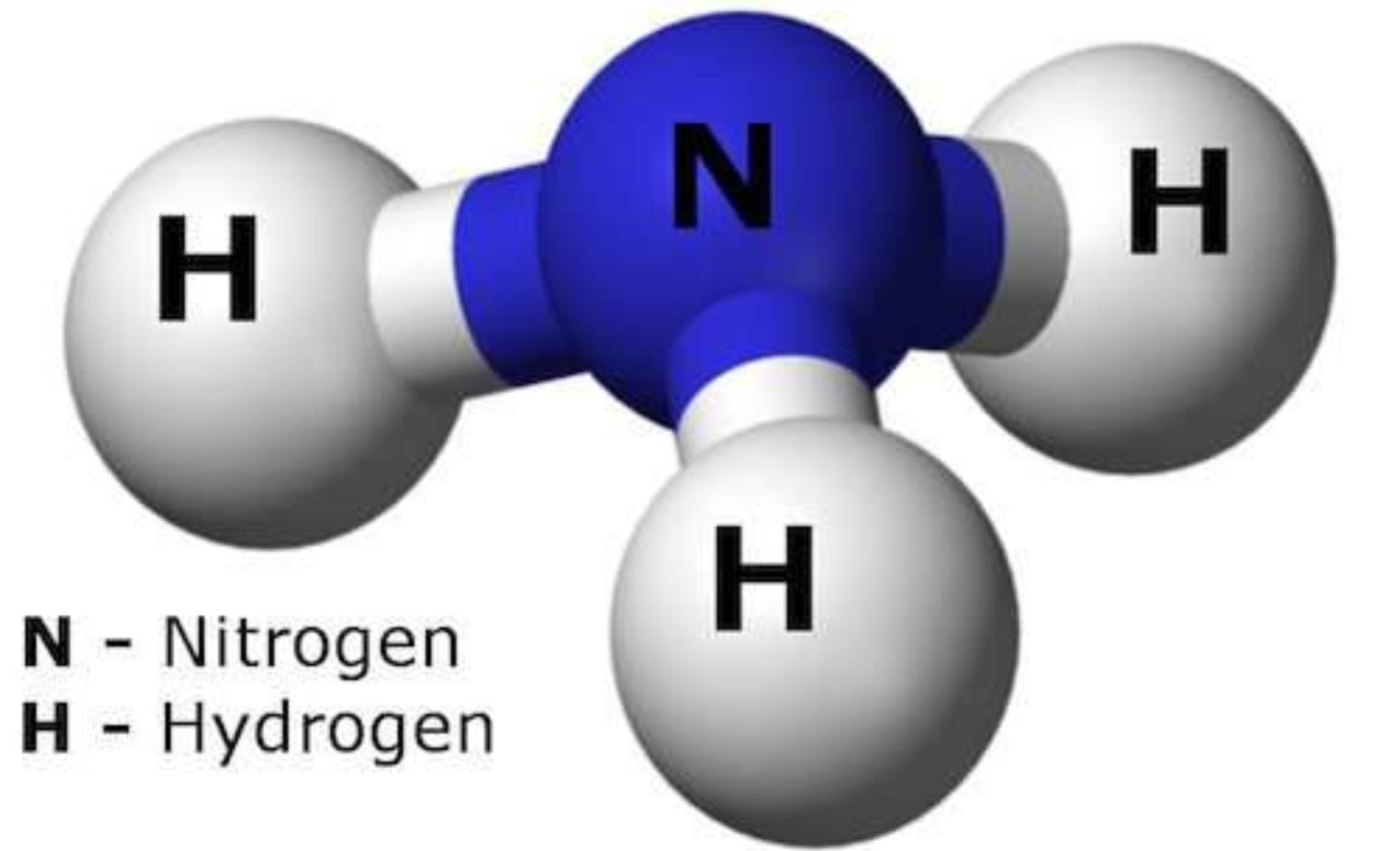

Ammonia is a promising, carbon-free fuel for meeting the IMO’s target of reducing greenhouse gas emissions from shipping by at least 50 percent by 2050. Although ammonia is derived mainly from fossil sources today, in the future ammonia’s greenhouse gas footprint can be nearly eliminated if it is produced using electricity from renewable sources.

Ammonia has a number of properties that require further investigation. It ignites and burns poorly compared to other fuels and is toxic and corrosive, making safe handling and storage important. Burning ammonia could also lead to higher NOx emissions unless controlled either by after-treatment or by optimizing the combustion process. A regulatory framework and class rules will need to be developed for its use as a marine fuel.

Wärtsilä aims to develop a complete ammonia fuel solution comprising engines, fuel supply and storage. The company is developing ammonia storage and supply systems as part of a project to install ammonia fuel cells on Eidesvik Offshore’s supply vessel Viking Energy by 2023. The company has also gained experience with ammonia from designing cargo handling systems for liquid petroleum gas carriers, many of which are used to transport ammonia.

Wärtsilä is investigating several future fuels, including synthetic methane, ammonia, hydrogen and methanol. Internal combustion engines can be adapted to burn any fuel, says the company. Dual-fuel or spark-ignited engines are already capable of burning LNG – from fossil, biomass or synthetic sources – while diesel engines can run on liquid biofuels, biodiesel or e-diesel. The modularity of modern engines means that conversions can be made with a very limited exchange of components.